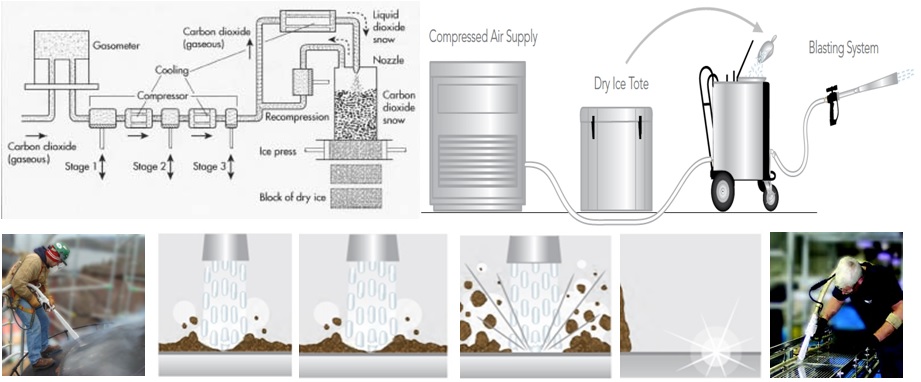

Dry Ice Blasting

Dry ice blasting has become the fastest growing application of CO2 in the entire industry. Similar to sand blasting, dry ice blasting uses a jet nozzle and compressed air to shoot small pellets of dry ice (blasting rice) with superior results. The extreme cold causes targeted material to shrink, allowing for easier removal. The used blasting rice will sublimate into gaseous CO2 after use which makes cleanup a breeze.

Advantages of Dry-Ice Blasting compared to Other Cleaning Methods

- No dismantling or re-assembly (even machine could be cleaned while on operation)

- Reducing cleaning time by 40-90%

- Reducing labor cost from 25-80%

- High cleaning speed even with inaccessible parts

- No waste disposal costs

- No chemicals or dissolvent used (only dry ice evaporates)

- Non abrasive, no wear and tear

- Blasting materials are not trapped nor detergent materials are left on the surface

- Not electrically conductive

- Non toxic as no chemicals are used

- No drainage of polluted water

- Easy waste management as the quantity of wasting material is minimized

- Safe work environment

DRY ICE VS. CONVENTIONAL CLEANING

|

CLEANING METHOD |

NO SECONDARY WASTE |

NON-CONDUCTIVE |

NON-TOXIC |

NON-ABRASIVE |

|

Dry Ice Blasting |

|

|

|

|

|

Sand Blasting |

|

|

|

|

|

Soda Blasting |

|

|

|

|

|

Water Blasting |

|

|

|

|

|

Solvents/Chemicals |

|

|

|

|

|

Hand Tools |

|

|

|

|

*Upon contact, traditional blasting materials become contaminated when used to clean hazardous substances and objects. These blasting materials are then classified as toxic waste and require appropriate safe disposal.